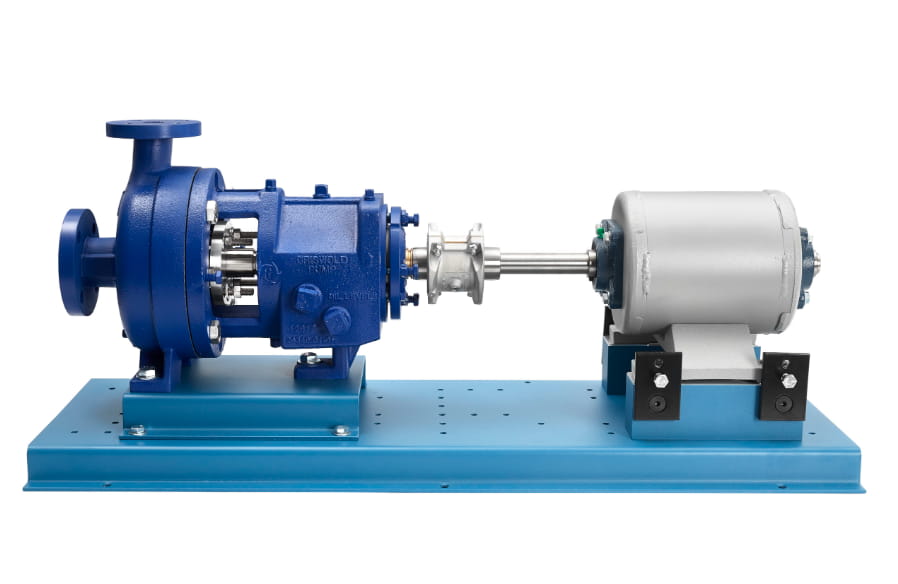

The industrial sector is vital to the global economy, and machinery is a key part of that. To keep the machines running smoothly and efficiently, it is crucial to have proper maintenance. Part of that maintenance is shaft alignment. To do shaft alignment properly, you need specialized shaft alignment training. The training not only covers the theory but also the practical applications.

The benefits of training are many. In this article, we will discuss the top 4 reasons why training is vital for machinery maintenance.

It helps to prevent costly repairs:

Instead of waiting for an expensive repair bill or machine failure, you can prevent costly repairs by having regular maintenance checks performed on your equipment. This includes routine inspections, maintenance checks and shaft alignment services. These checks can help identify potential problems before they occur so they can be repaired before things get worse. This reduces the risk of unexpected machine shutdowns and costly repairs later down the road.

It can help extend the life of your equipment:

Another benefit of shaft alignment and laser alignment training is that it can help extend the life of your equipment. If you do not perform proper maintenance on your machines, they will wear down faster and need more frequent repairs which will end up costing you money over time. By performing proper shaft alignment on a regular basis, you can reduce wear and tear on parts which results in fewer unscheduled maintenance shutdowns which save money over time.

It can reduce unexpected machine shutdowns:

When you are running an industrial facility, unexpected shutdowns can be a huge problem. If the machines come to a halt unexpectedly, then production stops and your business suffers losses as well as lost revenue from customers who were expecting deliveries on time. With proper alignment, these problems are avoided due to fewer breakdowns and less downtime overall.

It increases worker safety:

A poorly aligned shaft can cause an accident if it gets loose or breaks off unexpectedly while being operated by an employee or mechanic. This can lead to serious injuries such as broken bones and lacerations, which could land someone in the hospital for days or weeks at a time. By getting trained on how to properly align shafts and then doing so regularly, you can reduce the risk of injury at work sites significantly.

If you want to save money, keep your equipment running smoothly, and keep your workers safe, then you need shaft alignment training.