Geometric Measurement is critical for industrial machinery because it provides the critical data that is necessary for precision manufacturing. It is the branch of mathematics that deals with the precise relationships between points, lines, angles, surfaces, and solids.

Applications of measurement are found in many industries, including automotive, aerospace, and medical. For example, in the automotive industry, It is used to create models of car bodies and engine parts. In the aerospace industry, it is used to design and build aircraft, satellites, and rockets. In the medical industry, it is used to create implants and prosthetics.

The use of geometry is also growing in the field of nanotechnology. This is because the precise measurements required for this field are only possible with the use of specialized equipment.

How is it used in industrial machinery?

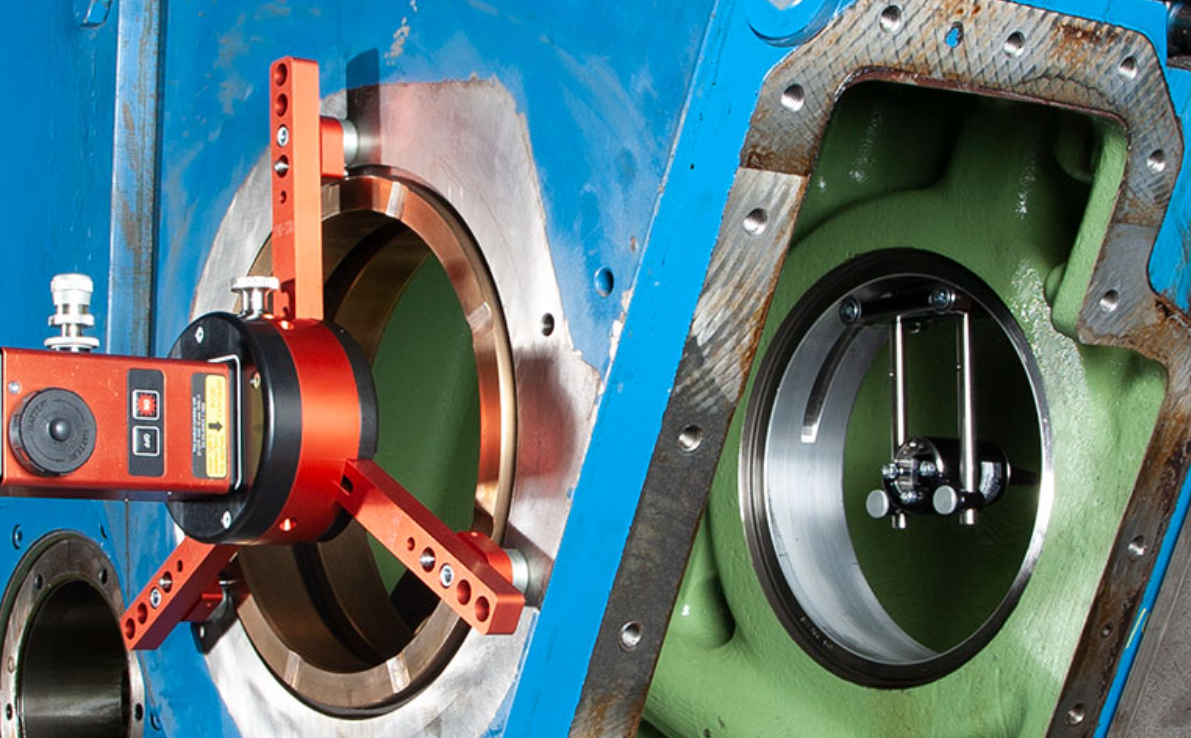

Industrial machinery used to laser shaft alignment services to determine accurate operational conditions for a machine. This includes measuring parts and assemblies as well as gauging finished products. The data collected from this process gives manufacturers an understanding of how well their products are performing and allows them to make necessary changes to improve overall efficiency.

The benefits of using geometric measurement include

Improving efficiency in production processes

It is an important part of every manufacturing process because it helps to improve the efficiency of production processes. For example, if your company manufactures car parts, then you would need to know how much metal should be used to make a particular product or how much space will be occupied by a particular part of the car body when finished. With this information, you can plan ahead and avoid waste of resources during production, which results in improved efficiency.

Reduces costs

They also help in reducing costs associated with manufacturing processes. This is because it provides accurate estimates about the amount of material needed for each project or task so that no wastage takes place, which reduces costs significantly as compared to using manual methods like using measuring tapes or rulers.

Accuracy

They provide high accuracy when it comes to measuring things

Reduced Error

They reduce errors by providing accurate measurements, which is essential for any industrial machinery.

Consistency

They provide consistency, which makes your drawings more accurate, reliable and genuine.

Conclusion

Geometric measurement is especially important in manufacturing because it can help to reduce errors during fabrication. Thus, part errors will be reduced, and the quality of machined parts will be increased. It can also improve any company’s bottom line.

Related Sources: laser alignment training, digital precision level